MIL-DTL-24607B is a semi-gloss, chlorinated alkyd enamel for interior use in marine and industrial environments. Once dry, this product is flame resistant and formulated to not burst into flame when directly exposed to shipboard fire conditions. This product is particularly suited for use on primed, interior surfaces of marine vessels and offshore platforms. It may be applied by brush, roller or spray to smooth metal, glass reinforced plastic (GRP), wood, and composite/plastic surfaces. Dry characteristics of this product include good retention of color and gloss as well as maintaining flexibility over time. This paint is a lead-free, non-chromate, and non-asbestos product. Complies with Detail Specification MIL-DTL-24607B (October 23, 2008), superseding DOD-E-24607A (July 1987) and DOD-E-24607 before that.

MIL-DTL-24607B is a semi-gloss, chlorinated alkyd enamel for interior use in marine and industrial environments. Once dry, this product is flame resistant and formulated to not burst into flame when directly exposed to shipboard fire conditions. This product is particularly suited for use on primed, interior surfaces of marine vessels and offshore platforms. It may be applied by brush, roller or spray to smooth metal, glass reinforced plastic (GRP), wood, and composite/plastic surfaces. Dry characteristics of this product include good retention of color and gloss as well as maintaining flexibility over time. This paint is a lead-free, non-chromate, and non-asbestos product. Complies with Detail Specification MIL-DTL-24607B (October 23, 2008), superseding DOD-E-24607A (July 1987) and DOD-E-24607 before that.

This reference site for MIL-DTL-24607 is provided as a courtesy by STIC-ADHESIVE Products Co., a manufacturer of this mil-spec coating.

Related NSNs

(top)

This list of NSN (National Stock Numbers) is for MIL-DTL-24607.

| MIL-DTL-24607 Chlorinated-Alkyd Enamel Color 24585, Pastel Green | ||||

| 24585, Pastel Green | 1 gallon | NSN 8010-01-344-5090 | See prices... | Request quote... |

| 5 gallons | NSN 8010-01-344-5101 | |||

| MIL-DTL-24607 Chlorinated-Alkyd Enamel Color 27880, Soft White | ||||

| 27880, Soft White | 1 gallon | NSN 8010-01-344-5089 | See prices... | Request quote... |

| 5 gallons | NSN 8010-01-344-5100 | |||

| MIL-DTL-24607 Chlorinated-Alkyd Enamel Color 26307, Bulkhead Gray | ||||

| 26307, Bulkhead Gray | 1 gallon | NSN 8010-01-344-5091 | See prices... | Request quote... |

| 5 gallons | NSN 8010-01-344-5102 | |||

| MIL-DTL-24607 Chlorinated-Alkyd Enamel Color 22563, Beach Sand | ||||

| 22563, Beach Sand | 1 gallon | NSN 8010-01-344-5085 | See prices... | Request quote... |

| 5 gallons | NSN 8010-01-344-5096 | |||

| MIL-DTL-24607 Chlorinated-Alkyd Enamel Color 22519, Rosewood | ||||

| 22519, Rosewood | 1 gallon | NSN 8010-01-344-5086 | See prices... | Request quote... |

| 5 gallons | NSN 8010-01-344-5097 | |||

| MIL-DTL-24607 Chlorinated-Alkyd Enamel Color 24516, Clipper Blue | ||||

| 24516, Clipper Blue | 1 gallon | NSN 8010-01-344-5087 | See prices... | Request quote... |

| 5 gallons | NSN 8010-01-344-5098 | |||

| MIL-DTL-24607 Chlorinated-Alkyd Enamel Color 23697, Sun Glow | ||||

| 23697, Sun Glow | 1 gallon | NSN 8010-01-344-5088 | See prices... | Request quote... |

| 5 gallons | NSN 8010-01-344-5099 | |||

| MIL-DTL-24607 Chlorinated-Alkyd Enamel Color 26496, Green Gray | ||||

| 26496, Green Gray | 1 gallon | NSN 8010-01-344-5092 | See prices... | Request quote... |

| 5 gallons | NSN 8010-01-344-5103 | |||

| MIL-DTL-24607 Chlorinated-Alkyd Enamel Color 26400, Yellow Gray | ||||

| 26400, Yellow Gray | 1 gallon | NSN 8010-01-344-5093 | See prices... | Request quote... |

| 5 gallons | NSN 8010-01-344-5104 | |||

| MIL-DTL-24607 Chlorinated-Alkyd Enamel Color 26493, Pearl Gray | ||||

| 26493, Pearl Gray | 1 gallon | NSN 8010-01-344-5094 | See prices... | Request quote... |

| 5 gallons | NSN 8010-01-344-5105 | |||

| MIL-DTL-24607 Chlorinated-Alkyd Enamel Color 25526, Pastel Blue | ||||

| 25526, Pastel Blue | 1 gallon | NSN 8010-01-344-5095 | See prices... | Request quote... |

| 5 gallons | NSN 8010-01-344-5106 | |||

MIL-DTL-24607B

23 October 2008

SUPERSEDING DOD-E-24607A 13 July 1987

INCH-POUND

(top)

DETAIL SPECIFICATION

ENAMEL, INTERIOR, NONFLAMING (DRY), CHLORINATED ALKYD RESIN, SEMIGLOSS

This specification is approved for use by all Departments and Agencies of the Department of Defense.

1. SCOPE

1.1 Scope. This specification covers a semigloss, chlorinated alkyd resin, interior enamel that does not support combustion or flaming when dry, and is for use on primed, smooth metal, glass reinforced plastic (GRP), wood and plastic/composite surfaces.

1.2 Classification. Enamel covered by this specification is chlorinated alkyd resin enamel furnished in the following colors as specified (see 6.1 and 6.2).

- Beach Sand, FED-STD-595 color number 22563

- Rosewood, FED-STD-595 color number 22519

- Clipper Blue, FED-STD-595 color number 24516

- Sun Glow, FED-STD-595 color number 23697

- Soft White (Formula 124), FED-STD-595 color number 27880

- Pastel Green (Formula 125), FED-STD-595 color number 24585

- Bulkhead Gray (Formula 126), FED-STD-595 color number 26307

- Green Gray, FED-STD-595 color number 26496

- Yellow Gray, FED-STD-595 color number 26400

- Pearl Gray, FED-STD-595 color number 26493

- Pastel Blue, FED-STD-595 color number 25526

2. APPLICABLE DOCUMENTS

2.1 General. The documents listed in this section are specified in sections 3, 4, or 5 of this specification. This section does not include documents cited in other sections of this specification or recommended for additional information or as examples. While every effort has been made to ensure the completeness of this list, document users are cautioned that they must meet all specified requirements of documents cited in sections 3, 4, or 5 of this specification, whether or not they are listed.

2.2 Government documents.

2.2.1 Specifications, standards, and handbooks. The following specifications, standards, and handbooks form a part of this document to the extent specified herein. Unless otherwise specified, the issues of these documents are those cited in the solicitation or contract.

FEDERAL SPECIFICATIONS

| TT-P-645 | - | Primer, Paint, Zinc-Molybdate, Alkyd Type |

FEDERAL STANDARDS

| FED-STD-141 | - | Paint, Varnish, Lacquer and Related Materials: Methods of Inspection, Sampling and Testing |

| FED-STD-595 color number 22519 |

- | Orange, Semigloss (Rosewood) |

| FED-STD-595 color number 22563 |

- | Orange, Semigloss (Beach Sand) |

| FED-STD-595 color number 23697 |

- | Yellow, Semigloss (Sun Glow) |

| FED-STD-595 color number 24516 |

- | Green, Semigloss (Clipper Blue) |

| FED-STD-595 color number 25526 |

- | Blue, Semigloss (Pastel Blue) |

| FED-STD-595 color number 24585 |

- | Green, Semigloss (Pastel Green, Formula 125) |

| FED-STD-595 color number 26307 |

- | Gray, Semigloss (Bulkhead Gray, Formula 126) |

| FED-STD-595 color number 26400 |

- | Gray, Semigloss (Yellow Gray) |

| FED-STD-595 color number 26493 |

- | Gray, Semigloss (Pearl Gray) |

| FED-STD-595 color number 26496 |

- | Gray, Semigloss (Green Gray) |

| FED-STD-595 color number 27880 |

- | Miscellaneous, Semigloss (Soft White, Formula 124) |

DEPARTMENT OF DEFENSE SPECIFICATIONS

| MIL-A-22262 | - | Abrasive Blasting Media Ship Hull Blast Cleaning |

| MIL-DTL-24441/20 | - | Paint, Epoxy-Polyamide, Green Primer, Formula 150, Type III |

| MIL-DTL-24441/29 | - | Paint, Epoxy-Polyamide, Green Primer, Formula 150, Type IV |

(Copies of these documents are available online at http://assist.daps.dla.mil/quicksearch/ or from the Standardization Document Order Desk, 700 Robbins Avenue, Building 4D, Philadelphia, PA 19111-5094.)

2.2.2 Other Government documents, drawings, and publications. The following other Government documents, drawings, and publications form a part of this document to the extent specified herein. Unless otherwise specified, the issues of these documents are those cited in the solicitation contract.

CODE OF FEDERAL REGULATIONS (CFR)

| 29 CFR 1910, 1915, 1917, 1918, 1926, and 1928 | - | Hazard Communication Act, Final Rule |

| 29 CFR 1910.1000 | - | Toxic and Hazardous Substances |

| 29 CFR 1910.1200 | - | Hazard Communication |

| 29 CFR 1990 | - | Identification, Classification, and Regulation of Potential Occupational Carcinogens |

| 40 CFR 60, Appendix A, Method 24 | - | Determination of Volatile Matter Content, Water Content, Density, Volume Solids, and Weight Solids of Surface Coatings |

| 40 CFR 82 | - | Protection of Stratospheric Ozone |

| 40 CFR 261, Appendix III | - | Toxicity Characteristic Method 1311 Leaching Procedure (TCLP) |

| 40 CFR 355, Appendices A and B | - | The List of Extremely Hazardous Substances and Their Threshold Planning Quantities |

| 40 CFR 372.65 | - | Specific Toxic Chemical Listings |

(Copies of these documents are available from the Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20401 or online at www.gpoaccess.gov/index.html.)

UNITED STATES ENVIRONMENTAL PROTECTION AGENCY (EPA)

| EPA SW-846 | - | Test Methods for Evaluating Solid Waste, Physical/Chemical Methods |

| EPA 600/4-020 | - | Methods for Chemical Analysis of Water and Wastes |

(Copies of this document are available from the Environmental Protection Agency, Ariel Rios Building, 1200 Pennsylvania Avenue, N.W., Washington, DC 20460, or www.epa.gov.)

2.3 Non-Government publications. The following documents form a part of this document to the extent specified herein. Unless otherwise specified, the issues of these documents are those cited in the solicitation or contract.

ASTM INTERNATIONAL

| ASTM D522 | - | Standard Test Methods for Mandrel Bend Test of Attached Organic Coatings (DoD adopted) |

| ASTM D523 | - | Standard Test Method for Specular Gloss (DoD adopted) |

| ASTM D562 | - | Standard Test Method for Consistency of Paints Measuring Krebs Unit (KU) Viscosity Using a Stormer-Type Viscometer (DoD adopted) |

| ASTM D823 | - | Standard Practices for Producing Films of Uniform Thickness of Paint, Varnish, and Related Products on Test Panels (DoD adopted) |

| ASTM D1210 | - | Standard Test Method for Fineness of Dispersion of Pigment-Vehicle Systems by Hegman-Type Gage (DoD adopted) |

| ASTM D1296 | - | Standard Test Method for Odor of Volatile Solvents and Diluents (DoD adopted) |

| ASTM D1364 | - | Standard Test Method for Water in Volatile Solvents (Karl Fischer Reagent Titration Method) |

| ASTM D1849 | - | Standard Test Method for Package Stability of Paint (DoD adopted) |

| ASTM D2244 | - | Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates (DoD adopted) |

| ASTM D2369 | - | Standard Test Method for Volatile Content of Coatings |

| ASTM D2805 | - | Standard Test Method for Hiding Power of Paints by Reflectometry |

| ASTM D3278 | - | Standard Test Methods for Flash Point of Liquids by Small Scale Closed-Cup Apparatus |

| ASTM D3359 | - | Standard Test Methods for Measuring Adhesion by Tape Test (DoD adopted) |

| ASTM D4400 | - | Standard Test Method for Sag Resistance of Paints Using a Multinotch Applicator |

| ASTM D5150 | - | Standard Test Method for Hiding Power of Architectural Paints Applied by Roller |

| ASTM D5895 | - | Standard Test Methods for Evaluating Drying or Curing During Film Formation of Organic Coatings Using Mechanical Recorders |

| ASTM E162 | - | Standard Test Method for Surface Flammability of Materials Using a Radiant Heat Energy Source (DoD Adopted) |

| ASTM E1252 | - | Standard Practice for General Techniques for Obtaining Infrared Spectra for Qualitative Analysis |

(Copies of these documents are available from ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959 or online at www.astm.org.)

THE SOCIETY FOR PROTECTIVE COATINGS (SSPC)

| SP 10 | - | Near-White Blast Cleaning (DoD Adopted) |

(Copies of this document are available from SSPC Publication Sales, 40 24th Street, 6th floor, Pittsburgh, PA 15222-4656 or www.sspc.org.)

2.4 Order of precedence. Unless otherwise noted herein or in the contract, in the event of a conflict between the text of this document and the references cited herein, the text of this document takes precedence. Nothing in this document, however, supersedes applicable laws and regulations unless a specific exemption has been obtained.

3. REQUIREMENTS

3.1 First article. When specified (see 6.2), a sample shall be subjected to first article inspection in accordance with 4.2.

3.2 Composition. Enamel shall consist of ingredients in the proportions specified in table I. Tinting pigments listed in table I may be varied as necessary to conform to color requirements. The use of alternate raw material ingredients may be proposed to NAVSEA. However, the alternate raw materials must be evaluated by NAVSEA and the enamel shall conform to all the requirements of this specification.

TABLE I. Color name and FED-STD-595 color number.

| Ingredients 1/ (pounds) | Soft white 27880 | Bulkhead gray 26307 | Rosewood 22519 | Pastel green 24585 |

|---|---|---|---|---|

| Chlorinated alkyd resin 2/ | 468.71 | 465.31 | 468.70 | 473.80 |

| Titanium dioxide 3/ | 214.82 | 211.38 | 212.91 | 215.23 |

| Magnesium silicate 4/ | 74.94 | 73.85 | 74.38 | 75.19 |

| Aluminum trihydrate 5/ | 195.94 | 194.52 | 195.94 | 198.07 |

| Calcium borosilicate 6/ | 98.44 | 97.72 | 98.43 | 99.50 |

| Calcium metaborate 7/ | 95.59 | 94.90 | 95.59 | 96.63 |

| PCBTF 8/ | 147.83 | 146.76 | 147.83 | 149.44 |

| Paint thinner 9/ | 35.55 | 35.30 | 35.55 | 35.94 |

| Thixatrope 10/ | 13.87 | 13.76 | 13.86 | 14.01 |

| Dispersant 11/ | 3.92 | 3.89 | 3.91 | 3.96 |

| Wetting agent 12/ | 3.07 | 3.04 | 3.07 | 3.10 |

| Anti-skinning agent 13/ | 2.91 | 2.88 | 2.91 | 2.94 |

| Cobalt drier 14/ | 0.92 | 0.91 | 0.92 | 0.93 |

| Zirconium drier 15/ | 0.91 | 0.90 | 0.91 | 0.92 |

| Yellow oxide paste 16/ | --- | 22.76 | 20.30 | 3.54 |

| Lamp black paste 17/ | --- | 8.40 | 0.39 | --- |

| Red oxide paste 18/ | --- | --- | 4.62 | 0.58 |

| Phthalo green paste 19/ | --- | --- | --- | 1.44 |

| Organic yellow paste 20/ | --- | --- | --- | 1.77 |

| Phthalo blue paste 21/ | --- | --- | --- | 0.26 |

| Totals | 1357.40 | 1376.28 | 1380.22 | 1377.24 |

TABLE I. Color name and FED-STD-595 color number -- Continued.

| Ingredients 1/ (pounds) | Green gray 26496 | Pearl gray 26493 | Clipper blue 24516 | Beach sand 22563 |

|---|---|---|---|---|

| Chlorinated alkyd resin 2/ | 472.12 | 474.85 | 471.3 | 468.40 |

| Titanium dioxide 3/ | 214.47 | 215.71 | 214.10 | 212.78 |

| Magnesium silicate 4/ | 74.93 | 75.36 | 74.80 | 74.33 |

| Aluminum trihydrate 5/ | 197.37 | 198.51 | 197.02 | 195.81 |

| Calcium borosilicate 6/ | 99.15 | 99.73 | 98.98 | 98.37 |

| Calcium metaborate 7/ | 96.29 | 96.84 | 96.12 | 95.53 |

| PCBTF 8/ | 148.90 | 149.78 | 148.65 | 147.73 |

| Paint thinner 9/ | 35.81 | 36.02 | 35.75 | 35.53 |

| Thixatrope 10/ | 13.96 | 14.05 | 13.94 | 13.85 |

| Dispersant 11/ | 3.94 | 3.97 | 3.94 | 3.91 |

| Wetting agent 12/ | 3.09 | 3.11 | 3.08 | 3.06 |

| Anti-skinning agent 13/ | 2.93 | 2.94 | 2.92 | 2.90 |

| Cobalt drier 14/ | 0.92 | 0.93 | 0.92 | 0.92 |

| Zirconium drier 15/ | 0.91 | 0.92 | 0.91 | 0.91 |

| Yellow oxide paste 16/ | 10.20 | 2.85 | 12.28 | 23.55 |

| Lamp black paste 17/ | 2.88 | 2.05 | --- | 0.38 |

| Red oxide paste 18/ | --- | 0.15 | 0.18 | --- |

| Phthalo green paste 19/ | --- | --- | --- | --- |

| Organic yellow paste 20/ | --- | --- | --- | --- |

| Phthalo blue paste 21/ | --- | --- | 2.71 | 0.06 |

| LF red paste 22/ | --- | --- | --- | 1.21 |

| LF orange paste 23/ | --- | --- | 0.16 | --- |

| Totals | 1377.87 | 1377.77 | 1377.75 | 1379.23 |

TABLE I. Color name and FED-STD-595 color number -- Continued.

| Ingredients 1/ (pounds) | Sun glow 23697 | Pastel blue 25526 | Yellow gray 26400 |

|---|---|---|---|

| Chlorinated alkyd resin 2/ | 460.77 | 473.18 | 471.70 |

| Titanium dioxide 3/ | 209.31 | 214.95 | 214.27 |

| Magnesium silicate 4/ | 73.12 | 75.09 | 74.86 |

| Aluminum trihydrate 5/ | 192.62 | 197.81 | 197.19 |

| Calcium borosilicate 6/ | 96.77 | 99.37 | 99.06 |

| Calcium metaborate 7/ | 93.97 | 96.50 | 96.20 |

| PCBTF 8/ | 145.32 | 149.24 | 148.77 |

| Paint thinner 9/ | 34.95 | 35.89 | 35.78 |

| Thixatrope 10/ | 13.63 | 14.05 | 13.95 |

| Dispersant 11/ | 3.85 | 3.95 | 3.94 |

| Wetting agent 12/ | 3.01 | 3.10 | 3.09 |

| Anti-skinning agent 13/ | 2.86 | 2.93 | 2.92 |

| Cobalt drier 14/ | 0.90 | 0.93 | 0.92 |

| Zirconium drier 15/ | 0.89 | 0.92 | 0.91 |

| Yellow oxide paste 16/ | 25.81 | 3.31 | 14.02 |

| Lamp black paste 17/ | --- | 0.63 | 1.00 |

| Red oxide paste 18/ | --- | --- | --- |

| Phthalo green paste 19/ | --- | --- | --- |

| Organic yellow paste 20/ | 15.39 | --- | --- |

| Phthalo blue paste 21/ | --- | 3.18 | --- |

| LF red paste 22/ | --- | --- | --- |

| LF orange paste 23/ | --- | 1.10 | 0.26 |

| Totals | 1373.17 | 1376.08 | 1378.83 |

TABLE I. Color name and FED-STD-595 color number -- Continued.

| NOTES: 1/ Formulas make approximately 100 gallons of paint. 2/ Becksol 91169-00, Reichold, Inc., Research Triangle Park, NC 3/ ASTM D476, Types I or II 4/ Omyacarb 3, OMYA Inc., Proctor, VT 5/ Aluminum trihydrate, SB-632, J.M. Huber, Edison, NJ 6/ CW-2230, Halox Pigments, Hammond, IN 7/ Calcium metaborate, BuLabFlame Block BL-381 Buckman Laboratories, Memphis, TN 8/ Oxsol 100®, Occidental Chemicals Corp., Dallas, TX (Oxsol 100(r) was used for this formulation. There are chemically identical alternatives available from other manufacturers.) 9/ Aromatic Naphtha, Ashland Chemicals, Columbus, OH 10/ Thixatrol SR, Elementis, Heightstown, NJ 11/ Spurso, OMG Americas, Cleveland, OH 12/ Anti-Terra 204, Byk-Chemie USA, Wallingford, CT 13/ Skino #2, OMG Americas, Cleveland, OH 14/ Cobalt Neodecanoate(12%), OMG Americas, Cleveland, OH 15/ Zirconium Neodecanoate(18%), OMG Americas, Cleveland, OH 16/ 5750V, UCD, Division of Rohm & Haas, Lansing, IL 17/ 1625V, UCD, Division of Rohm & Haas, Lansing, IL 18/ 6080V, UCD, Division of Rohm & Haas, Lansing, IL 19/ 5150V, UCD, Division of Rohm & Haas, Lansing, IL 20/ 5696V, UCD, Division of Rohm & Haas, Lansing, IL 21/ 4800V, UCD, Division of Rohm & Haas, Lansing, IL 22/ 7949V, UCD, Division of Rohm & Haas, Lansing, IL 23/ 6012V, UCD, Division of Rohm & Haas, Lansing, IL |

3.2.1 Metal content. The metal content (soluble and total) of the enamel shall be less than the values listed in tables II and III when tested in accordance with 4.5.1. If the test for total metal results in a value less than the soluble metal limit, the soluble metal test need not be conducted.

TABLE II. Soluble metals content.

| Soluble metal and its compound | Maximum, mg/L |

|---|---|

| Antimony | 15 |

| 5 |

|

| Barium (excluding barite) | 100 |

| Beryllium | 0.75 |

| Cadmium | 1 |

| Chromium (VI) compounds | 1 |

| Chromium and/or its chromium (III) compounds | 560 |

| Cobalt | 50 |

| Copper | 25 |

| Fluoride | 180 |

| Lead | 5 |

| Mercury | 0.2 |

| Molybdenum | 350 |

| Nickel | 20 |

| Selenium | 1 |

| Silver | 5 |

| Tantalum | 100 |

| Thallium | 7 |

| Tungsten | 100 |

| Vanadium | 24 |

| Zinc and its compounds | 250 |

TABLE III. Total metals content.

| Total metal and its compounds | Maximum, % wt. |

|---|---|

| Antimony | 0.015 |

| Arsenic | 0.005 2/ |

| Barium (excluding barite) | 0.10 |

| Beryllium | 0.0002 |

| Cadmium | 0.0005 |

| Chromium (VI) compounds | 0.001 2/ |

| Chromium and/or its chromium (III) compounds | 0.56 |

| Cobalt 1/ | 0.005 |

| Copper | 0.01 |

| Fluoride | 0.18 |

| Lead | 0.005 |

| Mercury | 0.0002 |

| Molybdenum | 0.35 |

| Nickel | 0.02 |

| Selenium | 0.002 2/ |

| Silver | 0.001 |

| Tantalum | 0.100 |

| Thallium | 0.007 |

| Tungsten | 0.100 |

| Vanadium | 0.01 |

| Zinc and its compounds | 0.25 |

| NOTES: 1/ Total cobalt content may exceed 0.005 wt. % (up to 0.2 wt. %) only if a cobalt drier is used to effect proper drying. Regardless of whether a cobalt drier is used, soluble cobalt content may not exceed table II requirements. 2/ Limit of detection of conventional laboratory analysis is in accordance with EPA Best Laboratory Practice. Values may be lower than those reported. |

|

3.2.2 Hazardous air pollutants (HAPs). The content of HAP solvents in the total enamel shall be not greater than the weight percent (% wt.) values listed in table IV when tested in accordance with 4.5.2.

TABLE IV. Hazardous solvent content.

| Hazardous solvent in total enamel | Maximum, % wt. |

|---|---|

| Benzene | 0.05 |

| Chlorinated solvent(s), total Carbon tetrachloride Chloroform (trichloromethane) Methylene chloride (dichloromethane) Tetrachloroethylene (perchloroethylene) 1,1,1-Trichloroethylene (methyl chloroform) Trichloroethylene |

0.05 |

| Ethyl benzene | 0.05 |

| Methyl, ethyl and butyl mono-ethers of ethylene glycol or the acetates, total (methyl, ethyl and butyl cellosolves, and acetates) |

0.05 |

| Methyl ethyl ketone (MEK) | 0.05 |

| Methyl isobutyl ketone (MIBK) | 0.05 |

| Toluene | 0.05 |

| Xylene (all forms) | 0.1 |

3.3 Color. The color, when tested in accordance with 4.5.3, shall be characteristic of the pigments specified in table I and shall match the colors as specified in table I and 1.2.

3.3.1 Color deviation. The color deviation of the paint shall be obtained as specified in 4.5.3.2. The measured color deviation (ΔE) from the specified FED-STD-595 color card in Commission Internationale de l'Eclairage (CIE) International Commission on Illumination LAB units shall be not greater than one CIELAB unit.

3.4 Toxins and carcinogens. The materials used in the coating compound, unless specific material maximum levels are cited in the specification, shall have no known carcinogenic or potentially carcinogenic materials identified by OSHA (29 CFR 1990) as regulated carcinogens, or IARC latest monographs, or the latest annual report of the NTP and shall have extremely hazardous substances (EHS) or toxic chemicals identified in 29 CFR 1910.1000, 40 CFR 355 and 372, respectively. The manufacturer shall not, unless specific material maximum levels are cited in this specification, allow the addition of any of these prohibited materials to the formulation. When any of these prohibited materials are or may be present, as a result of being present as a trace or impurity in another ingredient, the concentration of the prohibited material shall not equal or exceed 0.01 percent by weight of the coating compound (see 6.7). The enamel shall not contain more than 0.005 percent cobalt compounds by weight in its formulation, unless a cobalt drier is used (see table III). The enamel shall have no adverse effect on the health of personnel when used for its intended purpose (see 6.8). Questions pertinent to this effect shall be referred by the contracting activity to the appropriate service medical department that will act as advisor to the contracting activity.

3.5 Quantitative requirements. The enamel shall conform to the quantitative characteristics specified in table V when tested as specified in table VI.

TABLE V. Quantitative characteristics.

| Characteristic | Minimum | Maximum |

|---|---|---|

| Pigment content, percent by mass of enamel | 49.0 | 53.0 |

| Volatile content, percent by mass of enamel | --- | 27.0 |

| Total solids (percent) | 75.0 | --- |

| Coarse particles (percent) | --- | 0.5 |

| Water content (percent) | --- | 0.05 |

| Consistency (KU) | 75 | 85 |

| Weight per gallon (pounds) | 13.0 | 14.0 |

| Fineness of grind | 5.0 | --- |

| Drying time - to touch (hours) - dry hard (hours) |

--- --- |

4 8 |

| Gloss (60°) | 45 | 60 |

| Flash point °F (°C) | 100 (37) | --- |

| Color (ΔE) | --- | 1.0 |

| Sag resistance (mils) | 4 | --- |

| VOC (g/L) (pounds/gallon) | --- | 250 (2.1) |

| Contrast ratio | 0.90 | --- |

3.6 Qualitative requirements.

3.6.1 Condition in container. When tested as specified in table VI, a freshly opened full container of the enamel shall be free of grit, seeds, skins, lumps, putrefaction rancidity or livering, and shall show no more surface float (separated pigments or other ingredients on the surface of the liquid enamel) or pigment settling or caking than can be readily re-incorporated to a smooth uniform state (see 4.5.4.4).

3.6.2 Storage stability.

3.6.2.1 Partially-full container. When tested as specified in table VI, a three-quarter filled, closed 8-ounce (225-milliliter) glass jar of enamel shall show no skinning at the end of 48 hours and after aging as specified, the enamel shall show no skinning, surface float (separated pigments or other ingredients on the surface of the liquid enamel), livering, curdling, hard caking, or gummy sediment. The enamel shall mix readily to a smooth uniform state within 5 minutes when mixed with a paddle or mechanical mixer and shall have a consistency not greater than 5 units from the original Kreb unit consistency before testing (see table V). Enamel shall meet all other requirements of this specification (see 4.5.4.1).

3.6.2.2 Usability (full container). When tested as specified in table VI, the enamel in original unopened containers shall be usable for a period of 1 year of normal warehouse storage after the date of manufacture. The enamel shall show no skinning, livering, curdling, hard caking, or gummy sediment. The enamel shall mix to a smooth uniform state with no surface float (separated pigments or other ingredients on the surface of the liquid enamel) within 5 minutes when mixed with a paddle or mechanical mixer and shall have a consistency not greater than 15 units from the original Kreb unit consistency before testing (see table V). (see table VI and 4.5.4.2)

3.6.3 VOC regulations. Thinning of VOC compliant paint is not allowed. This paint is to be used as supplied without thinning (see table V and 4.5.5).

3.6.4 Brushing properties. When tested in accordance with 4.5.6, the enamel shall brush satisfactorily and shall dry to a uniform film, free from seeds, runs, sags, or streaks.

3.6.5 Rolling properties. When tested in accordance with table VI, the enamel shall roll satisfactorily and shall dry to a uniform film, free from seeds, runs, sags, or streaks. The dried film shall show an even, smooth finish.

3.6.6 Spraying properties. When tested in accordance with 4.5.8, the enamel shall spray satisfactorily and shall show no running, sagging, streaking, or orange peel. The air-dried film shall show no seeding, dusting, floating, mottling, hazing, or other film defects.

3.6.7 Odor. The odor of the wet enamel and the film at any interval of drying shall be characteristic of the volatiles permitted (see table VI).

3.6.8 Cross-cut adhesion test. When tested as specified in table VI, a 0.001-inch (nominal) [0.025-mm (nominal)] dry film of enamel shall achieve a minimum classification of 4B.

3.6.9 Flexibility. A film of enamel shall bend without cracking or flaking (see 4.5.9).

3.6.10 Recoating. When tested in accordance with 4.5.7, recoating of a dried film shall produce no film irregularities. The enamel shall not wrinkle or lift the first coat and shall dry to a smooth, uniform finish.

3.6.11 Appearance. When tested as specified in table VI, the enamel shall show no evidence of wrinkling or any other film defects and shall have a smooth and uniform appearance.

3.6.12 Nonflaming property. When tested as specified in 4.5.11, the enamel shall be resistant to burning. The test specimen shall show no flaming in excess of 5 seconds per ignition or dripping and have an average flame spread of index of 8 with no individual specimen having a flame spread index over 10.

3.6.13 Resistance to ignition. When tested as specified in 4.5.12, the enamel shall not exhibit flaming in excess of 5 seconds per ignition, sparking, or burning drops.

3.7 Batch specific VOC certification. The manufacturer shall prepare container label instructions for the enamel in accordance with the requirements of 29 CFR Parts 1910, 1915, 1917, 1918, 1926, and 1928 - Hazard Communication Act, Final Rule (see 6.9). To comply with the Environmental Protection Agency (EPA) National Emission Standards for Hazardous Air Pollution (NESHAP) requirements for shipbuilding and ship repair, the following two statements must appear on each paint can label:

a. A certification that the paint in the container meets the NESHAP requirements for shipbuilding and ship repair.

b. A statement of the ratio of volatile content to solids expressed as grams of volatile organic hazardous air pollutants (VOHAP) per liter of solids.

3.8 Material safety data sheet (MSDS). When specified (see 6.2), the contracting activity shall be provided a material safety data sheet at the time of contract award.

3.9 Ozone-depleting chemicals. The materials used in the enamel shall not contain Class I or Class II ozone-depleting chemicals as defined in 40 CFR 82.

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are classified as follows:

a. First article inspection (see 4.2).

b. Conformance inspection (see 4.3).

4.2 First article inspection. When specified (see 6.2), first article inspection shall be performed on a random sample drawn from the first production batch of enamel. First article inspection shall include all tests specified in table VI including those designated in table VI as a "conformance inspection test".

4.3 Conformance inspection. Conformance inspection shall consist of all tests specified in table VI with a footnote 1 notation.

4.3.2 Sampling for conformance testing. As a minimum, the contractor shall select a sample of sufficient size to permit the performance of all the inspections and tests as specified in table VI. If one or more defects are found in any sample, the entire lot (see 6.3.1) represented by the sample shall be rejected. If a lot is rejected, the contractor has the option of analyzing the rejected lot for the defective characteristic(s) and adjusting ingredients within allowed ranges as a new lot that shall be inspected and tested in accordance with table VI.

TABLE VI. Tests.

| Test | Requirements | Test Method |

|---|---|---|

| Soluble and total metals content 2/ | Tables II, III, and 3.2.1 | 4.5.1 |

| Hazardous air pollutants 2/ | Table IV and 3.2.2 | 4.5.2 |

| Color 1/ | 3.3 | 4.5.3 and ASTM D2444 |

| Pigment content 3/ | Table V | FED-STD-141 4021.1 |

| Volatile percent 3/ | Table V | ASTM D2369 |

| Density 3/ | Table V | ASTM D1475 |

| Appearance 3/ | 3.6.11 | ASTM D3359 |

| Condition in container 1/ | 3.6.1 | 4.5.4.4 and FED-STD-141 3011.2 |

| Storage stability partially-full container | 3.6.2.1 | 4.5.4.1, ASTM D1849, and FED-STD-141 3021.1 |

| Storage stability full container | 3.6.2.2 | 4.5.4.2 and ASTM D1849 |

| VOC 1/ | Table V | 4.5.5 |

| Brushing properties 1/ | 3.6.4 | 4.5.6 and FED-STD-141 4321.2 |

| Sag resistance 3/ | Table V | ASTM D4400 |

| Rolling properties 1/ 3/ | 3.6.5 | ASTM D5150 |

| Spraying properties 1/ | 3.6.6 | 4.5.8 and FED-STD-141 4331.1 |

| Odor 3/ | 3.6.7 | ASTM D1296 |

| Cross-cut adhesion tape test 1/ 3/ | 3.6.8 | ASTM D3359 |

| Flexibility | 3.6.9 | 4.5.9 and FED-STD-141 6221 |

| Resistance to ignition | 3.6.13 | 4.5.12 |

| Non-flaming properties | 3.6.12 | 4.5.11 and ASTM E162 |

| Flash point 1/ 3/ | Table V | ASTM D3278 |

| Water 3/ | Table V | ASTM D95 or D1364 |

| Coarse particles 1/ 3/ | Table V | FED-STD-141 4092.1 |

| Consistency 1/ 3/ | Table V | ASTM D562 |

| Fineness of grind 1/ 3/ | Table V | ASTM D1210 |

| Drying time 1/ 3/ | Table V | ASTM D5895 |

| Recoating | 3.6.10 | 4.5.7 |

| 60-degree specular gloss 1/ | Table V | ASTM D523 |

| Contrast ratio 3/ | Table V | ASTM D2805 |

| NOTES: 1/ Conformance inspection test (see 4.3). 2/ By vender certification. 3/ Test shall be conducted in accordance with the test method prescribed by this table. |

||

4.4 Test conditions. Unless otherwise specified (see 6.2), the routine and referee testing conditions shall be in accordance with FED-STD-141. The term referee condition shall mean a temperature of 73±2°F (23±1°C) and a relative humidity of 50±4 percent. A dry film thickness of 0.0015 to 0.002 inches (0.038 to 0.051 mm) shall be used whenever film thickness is requested in any test, unless otherwise required by the test. All paint test specimens shall be cured at least 16 hours at ambient laboratory conditions before testing unless otherwise specified (see 6.2).

4.4.1 Test panels and surface preparation. Unless otherwise specified (see 6.2), test panels shall be prepared as follows:

- Two sets of panels shall be prepared and all tests conducted with a panel of each set.

- Panels shall be steel having nominal dimensions of 6 inches by 12 inches by 0.125 inch (150 mm by 300 mm by 3 mm). Panels shall be prepared for testing by abrasive blasting to a near white surface in accordance with SSPC SP 10 to achieve a minimum 0.002 inch; 2.0 mil (0.050 mm) surface profile. The blasted panels shall be solvent wiped to remove any traces of oil or residue, blown dry with dry air, wrapped in plastic, and stored in either a desiccator or in other storage that will prevent rusting prior to coating. The abrasive used for blasting shall be in accordance with MIL-A-22262 and be listed on the current qualified products list (QPL).

- One set of panels shall be primed with primer provided in accordance with TT-P-645. The other set of panels shall be primed with primer provided in accordance with MIL-DTL-24441/20 or MIL-DTL-24441/29.

- Unless otherwise specified (see 6.2), primed panels shall be dried (cured) for 1 week at normal laboratory conditions or overnight at 104 to 122°F (40 to 50°C) before being topcoated.

- Unless otherwise specified (see 6.2), test coatings shall be applied in accordance with the manufacturers' instructions.

- The enamel shall be applied to the primed panels in two coats at a wet film thickness that will yield a dry film thickness of 0.002 to 0.003 inch (0.050 mm to 0.075 mm) per coat. Unless otherwise specified (see 6.2), dry time shall be 48 hours at 70°F (21°C).

- Where glass plates are specified for the test procedure, industry standard paper charts may be substituted for the test.

4.5 Tests.

4.5.1 Soluble and total metal content. Soluble and total metal content, except tantalum and tungsten, shall be determined on a dry paint film of the enamels in accordance with the 40 CFR 261, Appendix II and the appropriate test listed in tables VII and VIII. Soluble metal content shall be reported as milligrams per liter (mg/L). Total metal content shall be reported as percent by weight of the dry enamel film. The test results for metal shall be in conformance with the requirements of 3.2.1 and tables II and III. Tantalum and tungsten soluble metal content and total metal content shall be analyzed as specified in 4.5.1.1.

TABLE VII. Test methods for evaluating solid waste - physical/chemical methods, SW-846.

| Metal/material | Digestion test method |

|---|---|

| All metals, except chromium (VI) | 3050 |

| Chromium (VI) | 3060 |

| Metal/material | SW-846 analysis test method |

| Antimony | 7040 or 7041 |

| Arsenic | 7060 or 7061 |

| Barium | 7080 or 7081 |

| Cadmium | 7131 |

| Total chromium | 7190 |

| Chromium (VI) | 7195, 7196, or 7197 |

| Lead | 7421 |

| Mercury | 7470 or 7471 |

| Nickel | 7520 or 7521 |

| Selenium | 7740 or 7741 |

| Silver | 7760 or 7761 |

TABLE VIII. Methods for chemical analysis of water and waste, EPA-600/4-020, USEPA, 1979.

| Metal/material | Test method |

|---|---|

| Beryllium | 210.1 or 210.2 |

| Cobalt | 219.1 or 219.2 |

| Copper | 220.1 or 220.2 |

| Fluoride | 340.1, 340.2, or 340.3 |

| Molybdenum | 246.1 or 246.2 |

| Thallium | 279.1 or 279.2 |

| Vanadium | 286.1 or 286.2 |

| Zinc | 289.1 or 289.2 |

4.5.1.1 Tantalum and tungsten content. The tantalum and tungsten content of the enamel shall be determined using any appropriate spectroscopy test method. The tests shall be conducted in accordance with the instrument manufacturer's directions for the use of the instrument. The manufacturer is responsible for supporting the test method choice and analytical accuracy. The test results for tantalum and tungsten shall be as specified in tables II and III.

4.5.2 Hazardous air pollutants content. Hazardous air pollutant content shall be determined in accordance with Methods 7356 and 7360 of FED-STD-141. Solvent fractions shall be identified in accordance with ASTM E1252. Test results shall be reported as percent by weight of the total enamel. The test results for each solvent shall be in accordance with the requirement in 3.2.2 and table IV.

4.5.3 Color testing.

4.5.3.1 Instrumental color deviation determination. Test specimens shall be prepared in accordance with ASTM D823 Methods C or E using a nominal 0.006-inch blade film applicator onto a clear plate glass of not less than 3/8-inch (nominal) thickness which has been ground to a uniform finish with 1F carborundum. The color deviation shall be determined in accordance with ASTM D2244 using an instrument having a D65 light source, a 45-degree illumination angle, and a 0-degree viewing angle. The instrument shall be demonstrated to read the color of National Institute for Science and Technology (NIST [formerly National Bureau of Standards; SBS]) traceable standards with the color deviations of 3.3. After calibration of the instrument, measure the L, A, B color values of at least two FED-STD-595 color cards of the color being procured which were received from the Government not greater than 1 year prior to the date of this use. Calculate E for each color card. Determine the mean values of E, L, A, and B for the color cards. These mean values will be used to calculate the color difference values. The color values of the test enamel shall be measured. The color deviation terms shall be calculated. If using an instrument that automatically calculates the color differences, the color card mean values shall be entered as the base line for the color difference calculations. The results of the color deviation calculation shall be in accordance with the requirements of 3.3.1 and table V, as applicable.

4.5.3.2 Referee color matching. If the enamel measured in accordance with 4.5.3.1 does not match the color card when visually examined, the discrepancy shall be resolved by an independent laboratory certified to the NIST National Volunteer Laboratory Accreditation Program for paint testing. When tested in accordance with ASTM D823, the test enamel, prepared as specified in 4.5.3.1 shall visually match the FED-STD-595 color card that most closely corresponds to the mean values calculated in 4.5.3.1.

4.5.4 Storage stability and condition in container.

4.5.4.1 Partially-full containers. Skinning shall be determined after 48 hours in accordance with Method 3021.1 of FED-STD-141, except that a ¾-filled ½-pint, multiple friction top can shall be used. The can shall be resealed and aged for 7 days at 140°F (60°C) and examined for compliance with 3.6.2.1.

4.5.4.2 Full container. A full quart can of enamel shall be allowed to stand undisturbed for 12 months and then the contents tested in accordance with ASTM D1849. The contents shall be evaluated for pigment settling or caking as specified in 3.6.1, then agitate the can for 5 minutes on the paint shaker prior to re-examination. The viscosity shall be determined and other applicable tests made for compliance with 3.6.2.2.

4.5.4.3 Accelerated storage stability. After exposure to a temperature of 140°F (60°C) for a period of 30 days, a previously unopened, original container of enamel shall be examined for compliance with all the requirements of and the conformance tests of table VI with the exception of 3.6.2 3.6.12 and 3.6.13. The test results shall be in accordance with the requirements of this specification.

4.5.4.4 Condition in container. A container of the product shall be equilibrated to test laboratory conditions [nominal 73°F (23°C)]. Evidence of pressure or vacuum in the unopened container shall be noted. The container shall then be opened and examined in accordance with Method 3011.1 of FED-STD-141 for evidence of skinning, corrosion of container interior, odor of putrefaction, rancidity or souring, gel bodies, and hard settling. The enamel shall be hand-stirred 300 stirs in 2 minutes with a spatula appropriate to the container, stirring so as to ensure uniform distribution of any settled material. Immediately after stirring, the condition of the product shall be as specified in 3.6.1.

4.5.5 Volatile organic compounds (VOC). VOC content shall be determined in accordance with 40 CFR 60, Appendix A, Method 24. VOC content shall be as specified in table V (see 3.6.3).

4.5.6 Brushing properties. Brushing properties of the packaged enamel shall be determined in accordance with Method 4321.3 of FED-STD-141 for compliance with 3.6.4.

4.5.7 Recoating properties. Three panels shall be primed as specified in 4.4.1 with each primer. The first panel of each set shall have a 0.002- to 0.003-inch; 2- to 3-mil (0.051- to 0.076-mm) coating (topcoat) of paint applied, manufactured to MIL-PRF-24596. The second panel of each set shall have a 0.002- to 0.003-inch; 2- to 3-mil (0.051- to 0.076-mm) topcoat of Navy formula 25A, White applied. The third panel of each set shall have a 0.002- to 0.003-inch; 2- to 3-mil (0.051- to 0.076-mm) topcoat of the MIL-DTL-24607 test enamel applied that has been produced to this specification. After drying (curing the three panels for 48 hours at 122°F (50°C), the panels shall be cooled to ambient laboratory conditions and a 0.002- to 0.003-inch; 2- to 3-mil (0.051- to 0.076-mm) topcoat applied of the MIL-DTL-24607 test enamel. The enamel shall be examined for blistering, wrinkling, or peeling. The adhesion shall be checked by Method 6304.1 of FED-STD-141 except that the knife used may be an ordinary pocketknife or utility knife. Enamel condition shall be as specified in 3.6.10.

4.5.8 Spraying properties. The enamel shall be sprayed on a steel panel to a dry film thickness of 0.0009 to 0.0011 inch (0.023 to 0.028 mm). The panel shall be observed for spraying properties in accordance with Method 4331.2 of FED-STD-141 to determine compliance with 3.6.6.

4.5.9 Flexibility. Flexibility shall be determined in accordance with ASTM D522. The enamel shall be applied to a flat metal plate of approximately 31 gauge coated with a dry film thickness of 0.001 inch + 0.0003 inch (0.025mm) of TT-P-645 primer by means of a doctor blade capable of yielding a dry film thickness of 0.001 inch + 0.0003 inch (0.025 mm). The panel shall be allowed to air-dry for 2 hours then baked for 24 hours at 212 to 221°F (100 to 105°C). The panel shall then be removed from the oven and allowed to stand for 30 minutes at laboratory temperature [nominal 73°F (23°C)]. The panel shall then be bent over a 1/8-inch (3.2-mm) mandrel or a tapered mandrel where the minimum diameter is 1/8 inch (3.2 mm) and the film examined at the bent under a magnification of 5 diameters. Flexibility shall be as specified in 3.6.9.

4.5.10 60-degree specular gloss. The thoroughly mixed enamel on plane, opaque, black glass panels shall be as specified in ASTM D823. A film applicator shall be used that will produce a wet film thickness of 0.003 inch (0.075 mm). The enamel shall be dried 24 hours under referee conditions in a dust-free environment. Paint specimen shall be dry hard before gloss test. A longer cure time shall be used if required. When tested as specified in table VI, gloss shall conform to requirements of table V as applicable.

4.5.11 Non-flaming property. The non-flaming property of the test enamel shall be determined in accordance with ASTM E162. Test enamel shall be applied to three 1/8-inch thick cold rolled steel panels abrasive blasted to SSPC surface condition SP-10. Enamel shall conform to 3.6.12.

4.5.12 Resistance to ignition. The resistance to ignition test shall be conducted in accordance with Appendix A. Test results shall be in accordance with the requirements of 3.6.13.

4.6 Pigment content. The pigment content test shall be conducted in accordance with test method prescribed by table VI. Test results shall be in accordance with the requirements of table V.

4.7 Volatile percent. The volatile percent test shall be conducted in accordance with test method prescribed by table VI. Test results shall be in accordance with the requirements prescribed of table V.

4.8 Density. The density test shall be conducted in accordance with test method prescribed by table VI. Test results shall be in accordance with the requirements of table V.

4.9 Appearance. The appearance test shall be conducted in accordance with test method prescribed by table VI. Test results shall be in accordance with the requirements of 3.6.11.

4.10 Sag resistance. The sag resistance test shall be conducted in accordance with test method prescribed by table VI. Test results shall be in accordance with the requirements of table V.

4.11 Rolling properties. The rolling properties test shall be conducted in accordance with test method prescribed by table VI. Test results shall be in accordance with the requirements of 3.6.5.

4.12 Odor. The odor test shall be conducted in accordance with test method prescribed by table VI. Test results shall be in accordance with the requirements of 3.6.7.

4.13 Cross-cut adhesion tape test. The cross-cut adhesion tape test shall be conducted in accordance with test method prescribed by table VI. Test results shall be in accordance with the requirements of 3.6.8.

4.14 Flash point. The flash point test shall be conducted in accordance with test method prescribed by table VI. Test results shall be in accordance with the requirements of table V.

4.15 Water. The water test shall be conducted in accordance with test method prescribed by table VI. Test results shall be in accordance with the requirements of table V.

4.16 Coarse particles. The coarse particles test shall be conducted in accordance with test method prescribed by table VI. Test results shall be in accordance with the requirements of table V.

4.17 Consistency. The consistency test shall be conducted in accordance with test method prescribed by table VI. Test results shall be in accordance with the requirements of table V.

4.18 Fineness of grind. The fineness of grind test shall be conducted in accordance with test method prescribed by table VI. Test results shall be in accordance with the requirements of table V.

4.19 Drying time. The drying time test shall be conducted in accordance with test method prescribed by table VI. Test results shall be in accordance with the requirements of table V.

5. PACKAGING

5.1 Packaging. For acquisition purposes, the packaging requirements shall be as specified in the contract or order (see 6.2). When packaging of materiel is to be performed by DoD or in-house contractor personnel, these personnel need to contact the responsible packaging activity to ascertain packaging requirements. Packaging requirements are maintained by the Inventory Control Point's packaging activities within the Military Service or Defense Agency, or within the military service's system commands. Packaging data retrieval is available from the managing Military Department's or Defense Agency's automated packaging files, CD-ROM products, or by contacting the responsible packaging activity.

6. NOTES

(This section contains information of a general or explanatory nature that may be helpful, but is not mandatory).

6.1 Intended use. This specification covers high grade, air-drying enamels made from an alkyd resin and is intended for use on primed interior surfaces. It is characterized by excellent color and gloss retention, good drying, freedom from aftertack, and good flexibility. This enamel is a non-lead, non-chromate, and non-asbestos material. The dried paint film has been tested to USEPA standards and the paint debris is, as of the time of this specification, a non-hazardous waste. This enamel has been formulated to comply with air pollution regulations which allow a maximum VOC of 250 grams of solvent minus water per liter of paint (2.08 lb/gal) as delivered. This product is not to be thinned for all means of application. The enamel may be applied with brush, roller, or spray.

6.2 Acquisition requirements. Acquisition documents should specify the following:

a. Title, number, and date of this specification.

b. Color (number of color to FED-STD-595 recommended) required (see 1.2).

c. When first article is required (see 3.1).

d. Packaging requirements (see 5.1 and 6.9).

e. Whether MSDS and ASTM F718 data sheets are required with each shipment (see 3.8 and 6.6).

6.3 Definitions.

6.3.1 Lot. For the purpose of inspection and test sampling, a lot is defined as all the paint (in U.S. gallons) of the same type, class, grade, composition, and color from a single uniform batch, produced and offered for delivery at one time. The addition of any substance that was not present in the table I formulas will be considered a new lot for conformance testing.

6.4 Unit of procurement. The paint covered by this specification should be purchased by volume, the unit being 1 liter or 1 U.S. liquid gallon at 60°F (15.5°C).

6.5 Volatile content. Although the container marking specifically refers to Federal regulations, the paint may be used anywhere else a product complying with 1.2 is allowed. This includes other air pollution control districts or similar areas controlling the emission of solvents into the atmosphere.

6.6 Material safety data sheet (MSDS). The MSDS should be provided in accordance with OSHA section 1910.1200, 29 CFR Chapter XVII, and FED-STD-313. OSHA section 1910.1200 requires reporting threshold criteria for known or suspected human carcinogens on MSDS 0.1 percent or greater, and 1 percent or greater for other health hazards. The MSDS should be included with each unit of issue of material covered by the specification, when specified (see 6.2).

6.6.1 Material safety data sheets and ASTM F718. Contracting officers will identify those activities requiring copies of completed material safety data sheets prepared in accordance with FED-STD-313. The pertinent Government mailing addresses for submission of data are listed in FED-STD-313. When specified, ASTM F718 data sheet should be included with each shipment of the material covered by this specification (see 6.2).

6.7 Toxicity. Questions pertinent to this requirement should be referred by contracting activity to the qualifying activity. The qualifying activity will act as advisor to the contracting activity. The qualifying activity will arrange for a Health Hazard Assessment by the appropriate departmental medical service (see 3.4).

6.8 Toxicological product formulations. The contractor should have the toxicological product formulations and associated information available for review by the appropriate service medical department to evaluate the safety of the material for the proposed use.

6.8.1 Disclosure. A manufacturer of material should disclose the formulation of his product to the Navy Environmental Health Center, 620 John Paul Jones Circle, Suite 1100, Portsmouth, VA 23708-2103. The disclosure of proprietary information, which will be held in confidence by the Bureau of Medicine and Surgery, should include:

a. Name, formula, and approximate percentage by mass and volume of each ingredient in the product

b. Results of any toxicological testing of the product

c. Identification of its pyrolysis products

d. Any such other information as may be needed to permit an accurate appraisal of any toxicity problem associated with the handling, storage, application, use, or disposal of the material.

6.9 Suggested packaging requirements. Suggested packaging is contained in tables IX and X.

TABLE IX. Suggested packing and packaging.

| Packaging | Recommended requirements for direct Government acquisitions |

|---|---|

| Unit of procurement | The paints covered by this specification should be purchased by volume. The unit of procurement should be in multiples of 1 U.S. liquid gallon or 1 L at 15.5°C (60°F). |

| Containers | (a) The components should be furnished in cans of appropriate volume such as 3.78L (1-gallon) or multiples thereof. (b) Multiple friction plug containers should be in accordance with PPP-C-96, Type V, Class 2. Interior coatings should be as specified therein. Exterior coatings, including side seam stripping, should be as specified therein for plan B. Wire handles as specified therein, should be provided for the 1-gallon container. Closure of the properly filled and sealed cans should be as specified in the appendix thereto. (c) Pails should be to PPP-P-704. (d) All containers should comply with the requirements of the Uniform Freight Classifications (UFC), the National Motor Freight Classification (NMFC), and the applicable requirements of the Code of Federal Regulations 49 CFR, Department of Transportation (DOT). |

| Intermediate containers | (a) Paints should be packaged in intermediate containers. (b) Intermediate containers should be close-fitting corrugated fiberboard boxes in accordance with UFC, NMFC, and 49 CFR requirements. Fiberboard used in the construction of interior (unit and intermediate) and exterior containers, including interior packaging forms, should conform to the ASTM D4727. ASTM D4727 classes should be domestic fire-retardant or weather-resistant fire-retardant as specified. |

| Commercial packaging | (a) Commercial packaging should be to ASTM D3951. (b) All containers should comply with the requirements of the Uniform Freight Classifications (UFC), the National Motor Freight Classification (NMFC), and the applicable requirements of the Code of Federal Regulations 49 CFR, Department of Transportation (DOT). |

| Packing | Packing should be specified as follows: (a) Overseas delivery (Level A) packing. Intermediate containers of paint should be packed in close-fitting wood boxes conforming to ASTM D6251 or PPP-B-621, Class 2. Box closure and strapping should be as specified in the applicable box specification or the appendix thereto except that strapping should be flat and the finish B. (b) Domestic delivery (Level B) packing. Level B packing should be as for level A, except that boxes should be domestic type or class and the strapping should be finish A or B. (c) Commercial packing. The paint, in the specified unit and intermediate containers should, as applicable, be packed in multiples of like sizes in accordance with UFC, NMFC, and 49 CFR requirements. |

| Palletization | Intermediate containers should be palletized in accordance with MIL-HDBK-774. Only one size unit or intermediate container should be placed on a pallet. |

| Packing for Navy acquisitions | Treated lumber and plywood. All lumber and plywood, including laminated veneer materials, used in shipping container and pallet construction, member, blocking, bracing, and reinforcing should be fire-retardant treated material in accordance with MIL-L-19140 as follows: (a) General use, weather-resistant: MIL-L-19140, Type II, Category I. (b) General use, non-weather-resistant: MIL-L-19140, Type I, Category I. |

| MSDS and ASTM F718 | A copy of the MSDS and ASTM F718 should be attached to the shipping document for each destination (see 6.6). |

| VOC certification sheets | VOC certification sheets for each batch of coating will be provided when requested by the procuring activity. |

TABLE IX. Suggested marking.

| Marking type | Recommended marking |

|---|---|

| Bar codes | Marking should include bar codes |

| Hazardous warnings | (a) Labels should be in accordance with 29 CFR Parts 1910, 1915, 1917, 1918, 1926, and 1928, as well as PPP-P-1892. (b) All individual containers should have the following marking: (c) Each component container, shipping container, and palletized load should be marked with the appropriate hazardous symbol in accordance with FED-STD-313. |

| Volatile organic content (VOC) | "Contains a maximum of 250 grams of solvent of volatile organic compounds (VOC) per liter of paint per 40 CFR CH.1, part 60, Appendix A (EPA) Method 24." |

| VOC certification sheets/td> | VOC certification sheets shall be provided by the manufacturer of each batch of paint when requested by the procuring activity. |

| OSHA Hazard Communication Act and FED-STD-313 | Markings should include all information necessary to comply with OSHA Hazard Communication Act and FED-STD-313. |

| Mixing and use instructions | Directions should include mixing, application equipment directions, limitations on thinning, temperature range for use, and surface preparation recommendations. Directions should refer user to data sheets, MSDS, and ASTM F718 for information. |

6.10 Subject term (key word) listing.

Alkyd

Non-lead

Paint

Semi-gloss

Topcoat

Volatile organic content

6.11 Changes from previous issue. Marginal notations are not used in this revision to identify changes with respect to the previous issue due to the extent of the changes.

APPENDIX A

RESISTANCE TO IGNITION

A.1. SCOPE

A.1.1 Scope. This procedure determines whether a paint will ignite into flames when the sole ignition source is the heated metallic substrate to which the paint adheres. This Appendix is a mandatory part of the specification. The information contained herein is intended for compliance.

A.1.2 Resistance to auto-ignition. The test yields information on the ability of the coating to resist auto ignition, running and dripping when subjected to a very rapid heat rise and information on the ability of the paint to resist spread of the flame across the test specimen, as well as the tendency of a paint to ignite secondary flames by flaming drips.

A.1.3 Test conditions. The conditions of the test have been standardized so that paints passing this test may be safely used on ships' bulkheads and overheads where non-flaming paints are required to prevent fired from spreading from one sealed compartment to the next during a severe shipboard fire.

A.2. TEST APPARATUS

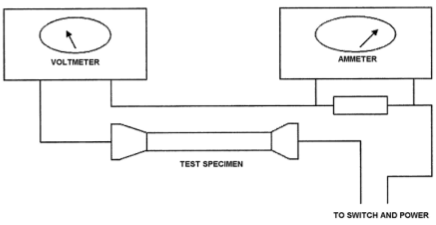

A.2.1 Test apparatus. The recommended apparatus consists of a high amperage direct current (DC) generator capable of 300 to 400 amps, electrodes for holding the specimen, an ammeter attached across an in-line shunt, a voltmeter, and a switch capable of handling the voltages and currents involved. The wiring diagram is shown on figure A-1 (found at the end of this Appendix A). The current from the DC generator is shunted directly through the test specimen to cause rapid heating. 3/0 stranded welding cable is recommended for wiring.

A.2.1.1 Test apparatus location. The test apparatus shall be arranged in a shielded cabinet or room to reduce air current effects. Air moving past the specimen shall be regulated to that caused only by convection heating of the test specimen.

A.2.2 Test panels preparation. Test specimens shall be coated to either 0.15 mm dry film thickness in as many coats as necessary to achieve 0.15 mm, or to that thickness recommended by the manufacturer's data sheet, whichever is greater. If multiple coats are required to achieve the test thickness, at least 24 hours, but no more than 48 hours shall lapse between coats. Fully coated test specimens shall be aged 14 days before being tested.

A.3. PROCEDURE

A.3.1 Calibration of temperature. Calibration of the 1832°F (1000°C) in 60 seconds time - temperature curves for the particular test specimens and power source shall be conducted. The time-temperature curve is determined by the cross section and resistivity of the actual test specimens used. Temperature-indicating crayons, temperature-indicating paints, or optical pyrometers are recommended. Thermocouples are not recommended due to the current flowing in the test specimen.

A.3.2 Test specimen observation. The test specimen shall be observed and the following shall be recorded:

A.3.2.1 Auto ignition. Flaming (ignition) of the paint before reaching 1832°F (1000°C).

A.3.2.2 Smoke generation. Fumes or smoke from the paint and the time at which fumes/smoke began.

A.3.2.3 Smoke observation (qualitative). Volume of smoke (light, moderate, or heavy).

A.3.2.4 Performance observations. Other characteristics, such as slouching, dripping, softening, or color changes.

A.3.2.5 Documentation. Video recording and color slides shall be taken during and after the test, particularly at the time of ignition and at the point of maximum involvement, and after the completion of the test.

A.3.3 Analysis of test results. Test results shall be in accordance with the requirements of 3.6.13.

APPENDIX A

A.4. SUMMARY

A.4.1 Summary of test method and results. This test procedure provides a relatively simple, straightforward, and reproducible method to determine the ignition potential of materials used to paint the interior surfaces of a compartment. In addition, important data on the reaction of the paint to heating of the substrate is determined. The fact that data is a "go" or "no-go" form makes the error of operation relatively small.

FIGURE A-1. Wiring diagram.

Custodians: Preparing Activity:

Army - CR4 Navy - SH

Navy - SH (Project 8010-0212-000)

Air Force - 99

Review Activities:

Army - MR

Navy - CG, MC, OS, YD

NOTE: The activities listed above were interested in this document as of the date of this document. Since organizations and responsibilities can change, you should verify the currency of the information above using the ASSIST Online database at http://assist.daps.dla.mil.

Comments, suggestions, or questions on this document should be addressed to: Commander, Naval Sea Systems Command, ATTN: SEA 05M2, 1333 Isaac Hull Avenue, SE, Stop 5160, Washington Navy Yard DC 20376-5160 or emailed to CommandStandards@navy.mil, with the subject line "Document Comment". Since contact information can change, you may want to verify the currency of this address information using the ASSIST Online database at http://assist.daps.dla.mil.

AMSC N/A FSC 8010

Resources

(top)

These external resources provide additional information about MIL-DTL-24607 and its applications.

- Articles about 24607 - National Surface Treatment Center

- Department of Defense Corrosion Prevention Website

- The Society of Protective Coatings - Standards

- Alkyd Coatings - National Surface Treatment Center

MIL-DTL-24607

MIL-DTL-24607